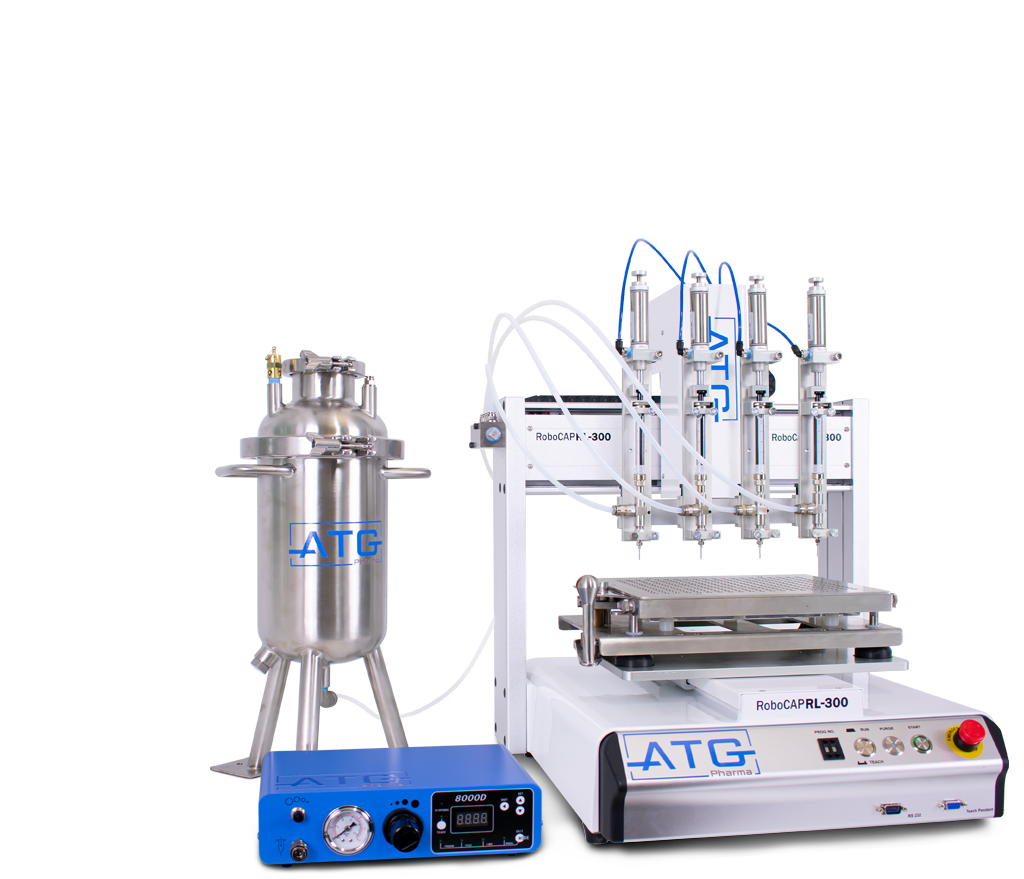

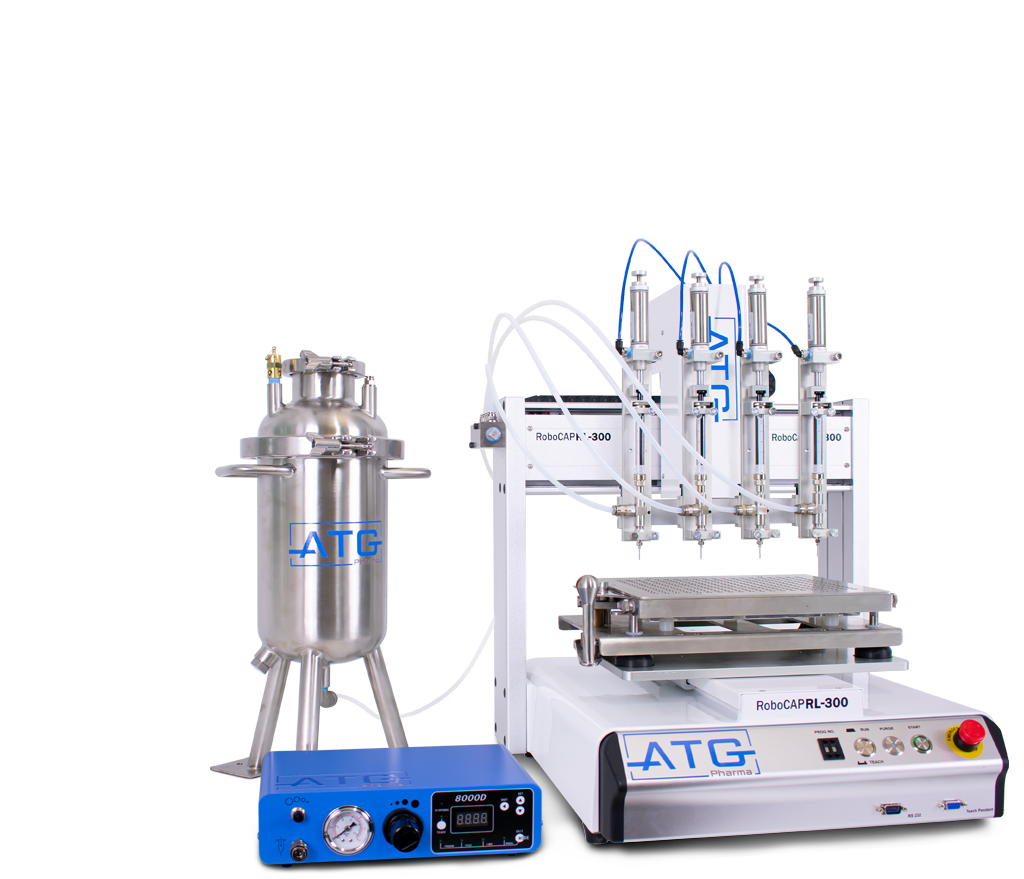

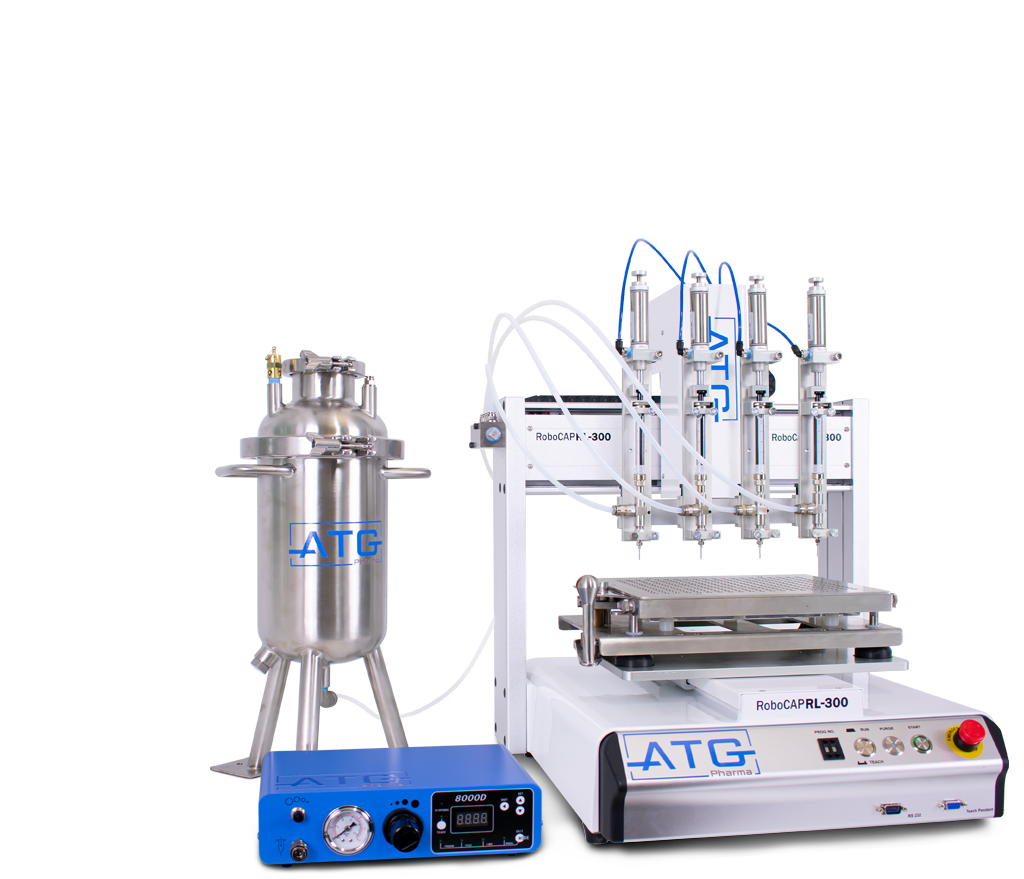

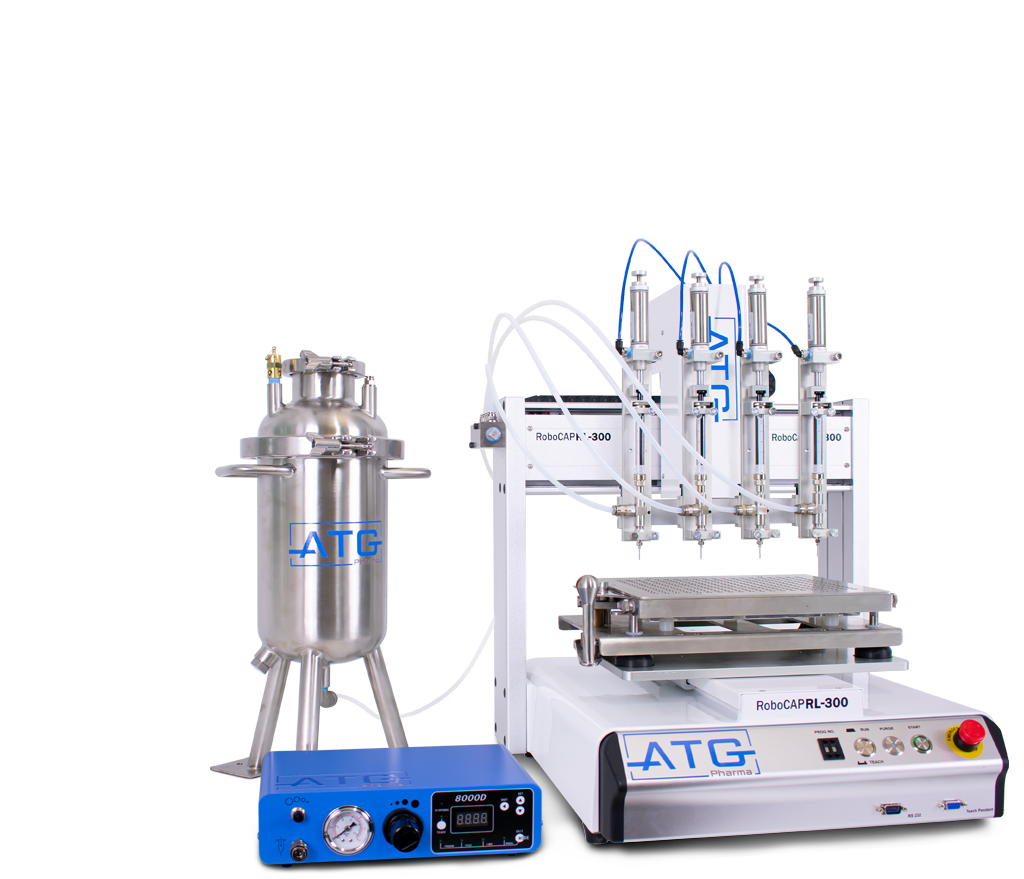

Whether you are a start-up or a well-established organization, the RoboCAP provides a filling system that has the ability to meet all your current and future filling needs with one robot. Providing the opportunity to scale as your production demands grow, the RoboCAP

The MonoBlox Product Suite consists of the MonoBlox, the MonoPress, and the MonoTray. This setup is ideal for filling & capping press top cartridges.

Increase Productivity with the ASCERA A-Block 3×3 Solution!

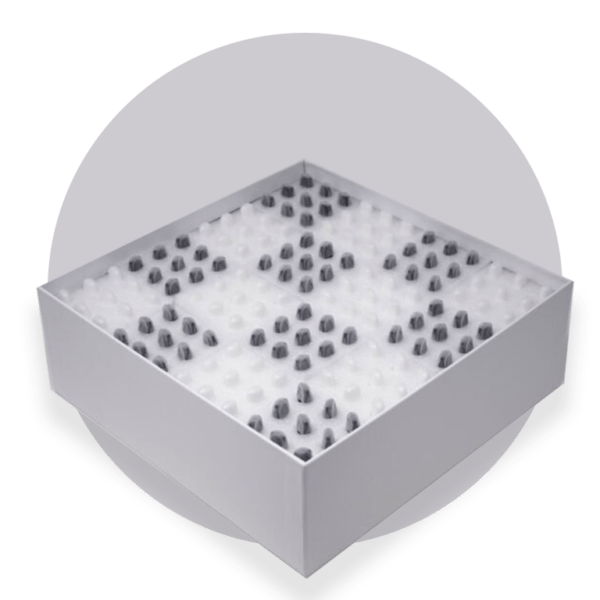

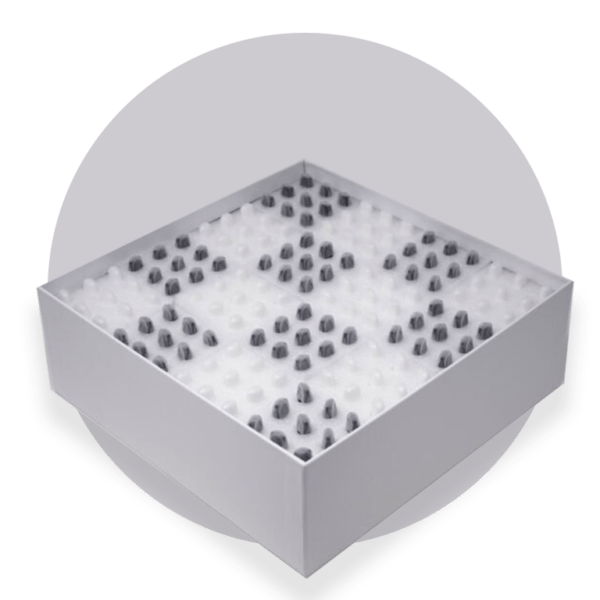

144 Pre-racked Cartridges on 16 MonoBlox, to be used with ATG Pharma’s MonoBlox Press

Designed to optimize low-volume product filling (up to 5ml) for maximum efficiency, our RoboCAP RL-300 Volumetric (VF) utilizes backpressure, heat and volumetric displacement to guarantee a +/- 2% filling accuracy with the same speed and consistency as our other RoboCAP systemsClients can upgrade to 2 nozzles with our heating and mixing system and 4 nozzles without heating to meet every company’s production demands!

Proprietary 3×3 block design optimizes throughput and removes unnecessary delays in production.

Pre-racked 3×3 trays arrive ready to take from packaging to filling. No more loading or unloading trays!

Lids racked in 3×3 foam, fitted perfectly for capping in the press with no additional setup.

Are you a non-industrial or small startup company? Get your production started right away with the ML-1 unit! Using the same parts and components as our semi-auto RoboCAP system, the ML-1 is an excellent starting point for businesses looking to auto their smaller batch products without compromising accuracy. When your production volumes increase, place your current ML-1 nozzle onto the RoboCAP to upgrade your production instantly.

FTL Distribution is the foremost Canadian distributor of ASCERA Zirconia Ceramic vape cartridges, Jiwa premium hand-rolled cones, and CR packaging to suit your brand.

Pair your ASCERA Zirconia Ceramic 510-vape cartridges or Jiwa pre-roll cones with extensive lineup of airtight, sustainable containers and inserts.

FTL Distribution is the foremost distributor of ASCERA Zirconia Ceramic 510-Vape Cartridges, Voltair Batteries and Jware premium hand-rolled pre-roll cones

Expertly crafted from Zirconia Ceramic, a highly durable, inert and pure material. Nearly as strong as steel, without the risk of oxidization, heavy metals, or ionic charge. Custom OEM branding opportunities available.

Work with FTL Distribution to secure your pre-roll cone supply production to receive exclusive manufacturer discounts.

Increase productivity with our various machines from ATG Pharma, Thompson & Duke and Futurola.

FTL Distribution is the foremost Canadian distributor of ASCERA Zirconia Ceramic vape cartridges, Jiwa premium hand-rolled cones, and CR packaging to suit your brand.

Pair your ASCERA Zirconia Ceramic 510-vape cartridges or Jiwa pre-roll cones with extensive lineup of airtight, sustainable containers and inserts.

FTL Distribution is the foremost distributor of ASCERA Zirconia Ceramic 510-Vape Cartridges, Voltair Batteries and Jware premium hand-rolled pre-roll cones

Expertly crafted from Zirconia Ceramic, a highly durable, inert and pure material. Nearly as strong as steel, without the risk of oxidization, heavy metals, or ionic charge. Custom OEM branding opportunities available.

Work with FTL Distribution to secure your pre-roll cone supply production to receive exclusive manufacturer discounts.

Increase productivity with our various machines from ATG Pharma, Thompson & Duke and Futurola.

FTL Distribution is the foremost Canadian distributor of ASCERA Zirconia Ceramic vape cartridges, Jiwa premium hand-rolled cones, and CR packaging to suit your brand.

Pair your ASCERA Zirconia Ceramic 510-vape cartridges or Jiwa pre-roll cones with extensive lineup of airtight, sustainable containers and inserts.

FTL Distribution is the foremost distributor of ASCERA Zirconia Ceramic 510-Vape Cartridges, Voltair Batteries and Jware premium hand-rolled pre-roll cones

Expertly crafted from Zirconia Ceramic, a highly durable, inert and pure material. Nearly as strong as steel, without the risk of oxidization, heavy metals, or ionic charge. Custom OEM branding opportunities available.

Work with FTL Distribution to secure your pre-roll cone supply production to receive exclusive manufacturer discounts.

Increase productivity with our various machines from ATG Pharma, Thompson & Duke and Futurola.